- Details

- Written by: Carlos Delgado

In the construction projects market, it is not unusual for the Purchasing area (or Procurement) to find itself under pressure to obtain results with no help from other areas. It seems as if asking Purchasing for something as vague as “concrete” should suffice to put things on track.

Actually, the procurement of goods and services is more a team effort than the sole responsibility of the Purchasing area. It is important to consider the specific responsibilities and capabilities of the Purchasing area: to timely put the requested goods or services on the specified location under the best commercial conditions.

“…to timely put the requested goods or services on the specified location under the best commercial conditions.”

That is already a lot. Purchasing needs to develop lists of approved suppliers depending on the goods or services needed and verify their capabilities, prepare tender packages, manage and answer technical and commercial questions, prepare comparison charts, negotiate commercial conditions and issue appropriate purchase orders or agree on contracts. And all this must be done on time considering that the Purchasing personnel is not, and could not be, technical specialists in all the several good and services they need to handle.

So, how can the purchasing specialists successfully fulfill their scope of work? The answer is with method and organization and involving other key areas from their organization.

The first key area is the “User” area. This User area needs to be clear in the scope of the supply needed. Therefore, it is essential that the User area develops a full and detailed scope of work/supply document describing with absolute clearness their request.

But that is not the end of the User area’s responsibility. In fact, the User area is in charge of some other sections of what the tender package will be: supervising standards, schedule, payment recognition procedure and target prices.

The supervising standards are crucial in construction projects, those standards define how the site crew, or production crew, would verify the physical work done on site, or what kind of access to the supervisor, or expeditor in case of goods, would be required.

Schedule requirements are easily forgotten in some cases. For concrete or reinforcing steel supply for example, it is critical to prepare a schedule showing the quantities needed on site as time progresses. This allows the suppliers to better assess their capabilities, the optimal way they can serve the project and offer the most economical alternative.

Suppliers of course would like to know the process they need to follow to get recognition about their work. Therefore, a document stating the payment recognition criteria should be prepared by the User area to be part of the tender package. That document shall define the

list of different items or services required, their corresponding units of measure, as well as the criterion for an item to be considered delivered.

In construction projects, as well as in other professional areas, it is vital to know how much we can spend. Obviously, any Purchasing area should be committed to obtain the lowest price with technical support and best commercial conditions, but it is highly recommended to have a target price in order to be in the position of assessing the suppliers’ proposals. This is important because that information is useful, not only as a “superior limit” for awarding suppliers or subcontractors, but because it helps to evaluate if some proposals are too low to be considered as professional and trustable or if our organization has a problem with its own cost estimates and the amount considered in its own contract is

inadequate. The target prices document is, therefore, internal to the organization and serves as an important reference to the Purchasing area, but it is not part of the tender package to be issued to the bidders.

Then, we have the Engineering area, in charge of the engineering package containing: drawings (blue prints), technical specifications, data sheets and all technical details to ensure the service or product is completely described and defined without a doubt.

Quality assurance and quality control (QA/QC) requirements should be fully disclosed to all bidders as part of the tender package, so QA/QC department is in charge of preparing a specific document for any tender. QA/QC requirements can have a strong impact in prices, and suppliers need to be aware of those requirements in advance to prepare trustable proposals. Failure in understanding QA/QC requirements is a source of risk and disputes in a construction project, but those problems are easily prevented by means of a well- prepared QA/QC requirements document for the tender process.

Construction projects are sources of health, safety, and environment (HSE) risks. HSE department is in charge of preparing a specific document to be part of the tender package. This is especially important for construction services and, depending on the type of project, there are different types of HSE risks that need to be addressed as per any applicable law. Law is quite severe regarding HSE in construction environments and the protection of the personnel working on site is of paramount importance, so the HSE document should consider the applicable law on the site jurisdiction.

The Legal area is in charge of preparing and providing a draft contract, especially useful for services. In the case of goods, the legal document can be limited to clauses intended to be included in the general or special purchasing conditions. The use of clear legal

requirements and draft contracts allows proposals better to fit the purpose and reduce the arising of disputes during the execution of the services.

At last, but not least, the Purchasing area is in charge of the Commercial Conditions, both general and special and the Purchase Order template. The Commercial Conditions are developed in close coordination with the Finance and Administration area and Legal area, and should cover topics such as period of valorization, payment time, type of disbursement, guaranties, and so forth.

Below is a chart showing the proposed purchasing package sections and responsibilities:

| Responsibility | ||||

| Item | Section | Generated by | Integrated by | Suppliers selection, tendering negotiation and award |

| - 01 - | Scope of Work | User Area | User Area |

Purchasing |

| - 02 - | Technical Specifications | Engineering | ||

| - 03 - |

QA/QC Requirements |

QA/QC Area | ||

| - 04 - | HSE Requirements | HSE Area | ||

| - 05 - | Supervising Standards | User Area | ||

| - 06 - | Schedule | |||

| - 07 | Payments recognition requirements | |||

| - 08 - | Target prices (internal document) | |||

| - 09 - | CommercialConditions | Purchasing | Purchasing | |

| - 10 - | Purchase Order Template | |||

| - 11 - | Contract Draft | Legal Area | ||

As shown, the User area is in charge of integrating the first eight sections, from Scope of Work up to Target Prices, and submit them to Purchasing.

Purchasing is in charge of preparing the Commercial Conditions and the Purchase Order Template and compiling those sections with the packages received from the User area and the Legal area. Then the Purchasing area prepares the suppliers list and the tender process including bidders invitation, proposals evaluation and comparison, award recommendation to management, final negotiation, and deal finalization with the awarded supplier.

As a consequence, it is clear that the purchasing process is indeed a team effort and there is no way a Purchasing area can effectively deliver appropriate goods and services without the key inputs from other areas of the organization, especially the User area.

The User area must be aware of its own importance and responsibilities. Without a proper scope of work and sufficient detail, including time of supply requirements, no Purchasing area would be able to succeed.

In times of change, when agility and economy are needed at all levels, the use of specialized services provides that precise mix of capacity, effectiveness and efficiency that organizations need to succeed.

At DC&R we are able to meet these requirements with professional solvency and the experience of more than 25 years in complex engineering and construction environments for heavy industrial markets of high demand such as mining, gas & oil, or energy, as well as for infrastructure and commerce.

DC&R also offers technical assistance services to businesses that need to interact with engineering and construction companies, from tender and project management to contract administration.

- Details

- Written by: Carlos Delgado

It is hard to overrate the importance of an appropriate and complete design for a project and its execution approach. With no consideration about if we are developing a family house or a big and complex industrial facility, design is fundamental, but the way to carry it out can make all the difference between success and failure.

How can we define a good project? First of all, it must be clear what the desired outcome and the owner's needs are. In small projects, aimed to particular clients, it is likely that the owner knows his/her desires, but it might exist some degree of unknown about his/her needs. The work with an experienced design leader (usually an Architect) must focus primarily on guiding the client along the issues that are not clear, in order to define the final product with the best detail.

When we talk about big complex and highly expensive industrial facilities, it is fundamental to understand that the owner needs to asses the “business case”. Yes, the owner of this type of project carries them out with only one objective: rentability.

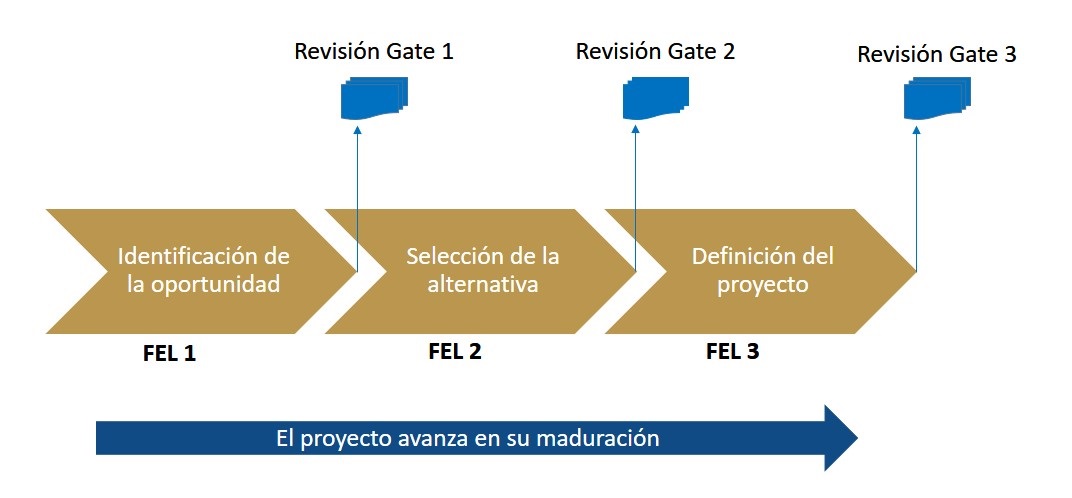

Therefore it is usual to use a “stage gate” approval methodology. The concept is simple, the project is divided into several steps, at the end of each one an assessment is performed and a decision is made about wether continue the project, modify or cancel it.

One of the best known methodologies in the market is the Front-End Loading (FEL). According to the “Construction Industry Institute”, FEL methodology is defined as the process of developing enough strategic information to allow defining the risks of the project and decide how to assign resources to maximise its chances of success.

Typically, a big and complex project goes through three FEL stages:

- FEL-1: It is the opportunity identification or business planning stage, and it is usually called also Preliminary Evaluation. The objective of this phase is to identify and support the opportunity, both technically and economically. This means that it might not exist a design, but only a quite rough economical estimation based on comparisons with similar projects, combined with the specific estimation of some costs. This is the concept studies phase.

- FEL-2: This is the phase of selection and scope development. In this phase possible alternatives are developed by means of trade-off studies, in order to select the more convenient alternative to take advantage of the business opportunity. It is the phase of the Preliminary Feasibility Studies, or “pre- feasibility” studies. Scott and Johnston report that most of the projects will go through two or more preliminary feasibility studies before a final feasibility study is performed

- FEL-3: Phase of project definition and project planning. Basic engineering, execution plan, budget and schedule are developed. This is the time for the Final Feasibility Study. Usually based on the most attractive alternative identified in the previous phase, this study aims to demonstrate conclusively that the project is technically sound and economically viable, produce sufficient support information to make the project bankable for financing institutions and provide a solid base to move to detailed engineering and construction without major changes.

Image: Ingenieros Top

Then the project moves to the execution stage. Consulting firm “Independent Project Analysis” (IPA) names this stage EPCC (Engineering, Procurement, Construction, and Commissioning).

It is in this execution or EPCC stage when the owner shall decide the execution method. The “Project Management Institute” (PMI) mentions in its Construction Extension of the PMBOK Guide as some of the most common methods for projects execution the following:

- Design-bid-build: This is the classic system by means of which the owner engages first the design, then bids the construction based on the engineering documents developed and the awarded bidder simply executes the construction according to the already defined design.

- Design-build: The owner buys the design and the construction to only one contractor based on a concept design and performance specifications developed by the owner.

- EPC (engineering, procurement and construction): Broadly known in the construction industry, the EPC transfers the full responsibility (and risk) for design, procurement and construction to the EPC contractor, who shall develop detailed engineering, buy equipment and supplies, and perform the complete construction to deliver an operative facility to the owner.

- Self-performance: Method used for small projects, usually maintenance. The owner does not engage a company, but performs the work using its own resources.

- IPD (integrated project delivery): This is a collaborative approach focussed on maximising the integration of the project teams, therefore the owner, the designer, the contractor and other stakeholders sign a single contract sharing risks and rewards, based on overall performance.

- Public-Private Partnership (PPP): Generally speaking, these are long term contracts with the State in which the ownership of the investments can be kept by, reverted or transferred to the State, based on the nature and scope of the project and the contractual provisions. These types of contract can be concession, operation and maintenance, management and any other as permitted by law2.

Selection of the project delivery method is of paramount importance. Depending on factors such as schedule, complexity, budget or particular needs of the project, the selection will vary.

When talking about big and expensive projects, it is reasonable that self-performance is usually out of the question. The classic design-bid-build method is the most used, especially in public projects. However, the outcome is not always the best. It is a simple and direct approach, but it requires time to adequately complete each stage and, during construction, a generally antagonistic relationship between the owner and the contractor is observed.

In private projects the arising of extra works and time extension requests lead the relationship between owner and contractor to complex levels of animosity and the results are delays, costs overruns and, sometimes, litigation.

Litigation is much more common in public projects that in the private sector. As an example, the Peruvian General Account Bureau (Contraloría General de la República - CGR) declared in March 2019, one year before the COVID-19 pandemic was declared in Peru, that in the country a total of 867 public construction projects were paralyzed, affecting investments of USD 4,400 million. Those days a local newspaper, Correo, reported that “After a study, the control bureau [CGR] determined that arbitration processes, deficiencies or contract breaches, as well as budgetary limitations of the public institutions are among the main causes that interrupted the execution”.

However, it is interesting to notice that the same year, 2019, Peru achieved a resounding success by delivering on time the construction projects for the Lima 2019 Pan American Games, using the IPD approach thanks to a Government-to-Government (G2G) agreement with the United Kingdom.

In the case of the main venue, La Videna, the project was executed in only 18 months from architectural design to complete construction. A total of 102,000 m2 with a budget over USD 152 million. A true world record.

We can hardly consider that the success of the Pan American Games Lima 2019 project was the product of chance. It is evident that an appropriate approach for project development and project execution allowed that the expertise, methodology and hard work of thousands of professionals get the maximum positive outcome.

In contrast, not long ago, in July 2021, the International Center for Settlement of Investment Disputes (CIADI) established after 4 years of an arbitral process that the Peruvian State failed to the existing concession contract with the Consortium Metro de Lima Line 2. The Consortium, formed by Cosapi, Impregilo, Iridium Concesiones de Infraestructura -subsidiary of ACS-, Vialia Sociedad Gestora de Concesiones de Infraestructura -subsidiary of FCC-, Ansaldo Breda and Ansaldo STS, filed the lawsuit in February 2017 with CIADI claiming compensation of more than USD 700 million and, following the July ruling in favour of the Consortium, in August 2021 the Spanish construction companies ACS and FCC, together with the Italian Impregilo and Ansaldo have filed a second arbitration claim against the Peruvian State.

Perhaps because of that, Peru has launched more projects using G2G agreements which allow approaches such as IPD, among them the new Central Highway and the Reconstruction With Changes.

In times of change, when agility and economy are needed at all levels, the use of specialized services provides that precise mix of capacity, effectiveness and efficiency that organizations need to succeed.

At DC&R we are able to meet these requirements with professional solvency and the experience of more than 25 years in complex engineering and construction environments for heavy industrial markets of high demand such as mining, gas & oil, or energy, as well as for infrastructure and commerce.

DC&R also offers technical assistance services to businesses that need to interact with engineering and construction companies, from tender and project management to contract administration.

- Details

- Written by: Carlos Delgado

Introduction

In the world of engineering and construction projects, success is often measured not only by meeting project goals but also by managing and mitigating risks effectively. These projects, especially in high-standard industrial markets like mining, gas & oil, and transport infrastructure, are complex endeavors that involve significant investments and potential hazards. In this article, we will delve into the critical aspect of risk management in these industries.

“In the field of engineering and construction projects, risk management is not an option; it's a necessity”

Understanding the Landscape

Before embarking on any engineering or construction project, it's vital to comprehensively understand the risk landscape. In Peru, where I am based, projects in mining, gas & oil, and transport infrastructure are prominent. Each of these sectors comes with its unique set of risks.

- Geological and Environmental Risks: In mining and gas & oil projects, geological conditions and environmental impacts are key concerns. Unforeseen geological formations, natural disasters, and environmental regulations can all pose significant risks.

- Supply Chain and Logistics Risks: Given their involvement in critical equipment, logistics risks should not be underestimated. Delays in the supply chain can have a cascading effect on project timelines and costs.

- Regulatory and Compliance Risks: Strict regulations often govern these industries, and non-compliance can result in substantial penalties. Staying abreast of changing regulations is crucial.

- Technology and Innovation Risks: As technology evolves, incorporating the latest innovations can be both an opportunity and a risk. It's essential to assess the maturity and reliability of new technologies before integrating them into projects.

- Economic Risks: Economic factors, such as currency fluctuations and inflation, can impact project budgets and profitability. Effective financial risk management is essential.

- Community Relations Risks: In Peru, this is often the most critical of all risks, especially to mining and oil & gas projects. Obtaining the social license has paralyzed more than one big project, and caused extended delays to most of the rest.

Mitigation Strategies

Given the diverse range of risks, a comprehensive risk management strategy is imperative. Here are some key steps:

- Risk Assessment: Begin with a thorough risk assessment, identifying potential risks and their potential impact on the project. Consider both internal and external factors.

- Risk Mitigation Plans: Develop specific mitigation plans for each identified risk. These plans should outline preventive measures, contingency plans, and responsible parties.

- Project Planning: A well-structured project plan that considers risk factors can help in risk avoidance. Ensure that timelines are realistic and that resources are allocated appropriately.

- Insurance Coverage: Explore insurance options that can provide coverage for unforeseen events. This can include construction and liability insurance.

- Contractual Agreements: Carefully draft contracts with suppliers, contractors, and other stakeholders. These agreements should include clauses that address risks and responsibilities.

- Monitoring and Reporting: Implement a robust system for monitoring project progress and tracking risks. Regular reporting and review meetings are crucial to keep all stakeholders informed.

Conclusion

In the field of engineering and construction projects, risk management is not an option; it's a necessity. The high-stakes nature of projects in industries like mining, gas & oil, and transport infrastructure demands meticulous planning and vigilance. By understanding the risk landscape, implementing mitigation strategies, and staying adaptable, project managers can increase the likelihood of successful project outcomes.

In conclusion, whether you're constructing a new airport or working on a massive mining operation, risks are an inherent part of the journey. Embracing effective risk management not only safeguards your investment but also paves the way for a more sustainable and prosperous future in the world of high-standard industrial projects.

In times of change, when agility and economy are needed at all levels, the use of specialized services provides that precise mix of capacity, effectiveness and efficiency that organizations need to succeed.

At DC&R we are able to meet these requirements with professional solvency and the experience of more than 25 years in complex engineering and construction environments for heavy industrial markets of high demand such as mining, gas & oil, or energy, as well as for infrastructure and commerce.

DC&R also offers technical assistance services to businesses that need to interact with engineering and construction companies, from tender and project management to contract administration.

- Details

- Written by: Carlos Delgado

What is an EPC Contract?

First things first, I should clarify that here we will refer to a particular field: engineering and construction projects in heavy industries such as mining, oil & gas, energy, etc.

Let us start from the beginning: what is an EPC contract? EPC stands for Engineering, Procurement and Construction. This means that an EPC contract is no different than any other contract, under whatever terms of payment and risk distribution client and contractor might want to agree upon, but it includes the design, purchases and construction of a specific project in the scope of work.

EPC contract must not be mistaken as the EPCM contract, where the CM stands for Construction Management, meaning that the contractor does not perform the construction by itself, but manages it through one or several contractors for construction. The CM contractor becomes the client´s “project construction management team”.

How come a client sees the Lump Sum EPC Contract as a guide?

EPC Contracting systems

In our market it is typical to think of a specific EPC Contract type: Lump Sum. Just to be in the same page, what is the definition of Lump Sum? Once I had a disagreement with a client (a friend and engineer, like me) and, since the answer involved a nice amount of money, the fair thing to do was to look for a neutral, technical and somehow “close-to-official” source for the private sector: the Public Contracting Law. (I am based in Peru) The Peruvian Public Contracting Law states:

“Contracts use the following contracting systems:

- Lump Sum, applicable when quantities, magnitudes and qualities are defined in the

technical specifications, reference terms or, in the case of construction works, in the

corresponding drawings, technical specifications, descriptive report and construction budget.

The bidder shall present its offer for a fixed amount and a defined execution term, to fulfill the

requirement. (…)”

The most common situation is that everybody has in mind something like “The bidder shall present its offer for a fixed amount and a defined execution term, to fulfill the requirement” and not necessarily the concept of “…applicable when quantities, magnitudes and qualities are defined in the technical specifications, reference terms or, in the case of construction works, in the corresponding drawings, technical specifications, descriptive report and construction budget”.

Wait a moment! Defined quantities, magnitudes and qualities? But, if we are talking about an EPC, which means that the contractor shall take care of the engineering, how could we have defined quantities, magnitudes and qualities? Exactly, …we do not have them.

Before going deeper into the problems this incongruence brings, it is good to know that there is no obstacle to use an EPC contract with some of the other existing contracting types such as Unit Prices, a mix between Lump Sum and Unit Prices or, even some open book cost-reimbursable agreement, meaning that real costs are shown, and a fee is paid to the contractor.

We should also say that clients (clients are usually the most enthusiastic about Lump Sum EPC contracts) have in mind that EPC implies “turnkey”, which means that “…the bidder’s proposal includes the construction, equipment and erection up to commissioning and, if necessary, technical dossier and/or assisted operation of the project.”

As a summary, in our market the EPC Contract has the marketing position of a Turnkey-Lump Sum Contract, despite that is only one of several options.

Risks of a Lump Sum EPC Contract

So far, we have seen that a Lump Sum contract is applicable when the engineering of a project is essentially ready: it has drawings, specifications, descriptive report, etc., therefore quantities and qualities are already defined.

This happens because, when a project is well developed and its engineering is essentially complete, the risk of errors in a bidder’s proposal is low. It is expected that the proposals are complete, and the price and delivery term are appropriate.

But what happens when a client asks for Lump Sum EPC proposals? Obviously, the client should have a minimum design for its project, a basic engineering development able to provide the bidders enough information in order the proposals to fit the client’s expectations.

If we were talking about a house, the client should be clear in its needs and expectations: how many bedrooms, bathrooms, which bedroom should have incorporated a bathroom, if a parking garage is needed and, if so, for how many vehicles, etc.

In our case, EPC contracts in heavy industry markets, the issue is a bit more complicated, but the concept is quite similar.

When a bidder faces a Lump Sum EPC bid, immediately realizes its high-risk exposure and the need to take precautions. We are here considering experienced and diligent bidders.

As a first step, it assembles an engineering team to develop a pre-design that allows to estimate quantities and qualities for a substantial part of the most important works, and their impact in cost and delivery term. It is even possible that the bidder engages an engineering firm for this pre-design.

In addition to that, since the bidder knows that the quantities it may estimate might not be accurate enough, it will probably add some “reserves”, as a contingency, to its estimation of quantities, costs and delivery term; as well as a general contingency according to the risk taken. As it is to be expected, the bidder’s cost and delivery term will also include a specific task for the ready-for-construction detailed engineering development.

The time needed for the detailed engineering development also affects the costs, since it can delay the start of the purchases beyond the validity time frame of the quotations the bidder obtained for its proposal, so it is common to include also allowances for price escalation.

In short, this type of bid generates proposals with longer delivery term and higher prices than the proposals from “classic” bids with well-defined and complete engineering or any of the other EPC contract types using Unit Prices or some cost-reimbursable contract. This is the direct consequence of the high risk of the operation.

From the client’s point of view, why ask for a type of bid which, quite certainly, will offer higher prices and a longer delivery term? How come a client sees the Lump Sum EPC Contract as a guide?

Primarily, due to the certainty about the delivery term and the cost that a Lump Sum EPC contract can provide. The over-price paid by the client is like an insurance against additional costs and time extensions. It is the cost of transferring the risk to the contractor.

Certainly, the risk balance leans strongly to the contractor’s side - more than what is reasonable, if I may say - and this brings some problems.

The first of them is that a wrong estimation can cause losing the bid, in case of an over-estimation or, much more serious, the case of an under-estimation that ends in the award of a proposal which will generate the loss of money to the lucky winner bidder. A loss means that the contractor ends with less money than in the case of not executing the project. In short, not being awarded would have been a better situation.

We could call this last situation a Pyrrhic victory, named after King Pyrrhus of Epirus, whose army suffered so many casualties in defeating the Romans, that it is said he exclaimed: “If I achieve such a victory again, I shall return to Epirus without any soldier”.

The case is, this kind of Pyrrhic victories are quite common in the world of Lump Sum EPC contracts due to the high complexity of the projects, so the chances of errors are high. In a typical bidding process, someone over-estimates, so it loses the bid; a group of bidders’ proposals go aligned inside a “reasonable range“ of prices; while is highly possible that one bidder, at least one, under-estimates. If the bidders are financially strong companies, we have our happy winner, our own King Pyrrhus.

It is obvious that, sooner or later, the awarded contractor will realize that it is going to lose money, usually a big amount, so it will be tempted to look for any chance of recovering money or saving it.

Some strategies to achieve this will be quite valid and acceptable: having the engineering of the project as part of its scope of work, the contractor can analyze changes, reductions and any type of adjustments intended to save cost or time. As long as the client’s acceptance criteria are met, meaning that the contract is fulfilled, the client has no reason to complain.

The real problem arises because it is possible that the contractor, already deep in the problem of an important loss of money, might be tempted to use unacceptable or unethical strategies.

It is then that we run into an undesirable situation.

Equally undesirable, although morally acceptable, is if the contractor explains the situation and asks for a termination of the contract; if such an action, with all the punishing costs usually associated, is for the contractor less harmful that finishing the project.

When to use an EPC Contract?

From my point of view, the EPC contract, with all its variations, is just a tools box, but as such, each tool will be useful as far as the selected tool is fit to the job.

In the case of the Lump Sum EPC, it can be used for specific scopes of work for which a highly specialized supplier is required and, therefore, such supplier already has of-the-shelf designs ready and needing only minor adjustments to fit the project: office containers, frigorific chambers in a client’s specific room, etc.

On the contrary, a Lump Sum EPC contract is not recommendable for large and complex projects with the integration of several disciplines and highly technical supplies from diverse vendors. Classic case: a mining concentration plant. For such cases, if in order to shorten the delivery term, the decision is to use an EPC contract, it is better to use Unit Prices or some cost-reimbursable agreement.

This last few years collaborative contracts are being introduced. The concept is simple, but very interesting: the client pays all costs, and the contractor earns a fee. Any bonus or penalty goes against its fee, but penalties never can exceed it, so, even in the worst-case scenario, the contractor earns nothing but is in no risk of paying costs that would not be recovered. This system involves additional tenets such as sharing the management and outcome of risks, collaboration instead of confrontation, unanimous decisions, focus on results and solutions not in assigning responsibilities, and full costs transparency.

I firmly believe that is the way to go.

In times of change, when agility and economy are needed at all levels, the use of specialized services provides that precise mix of capacity, effectiveness and efficiency that organizations need to succeed.

At DC&R we are able to meet these requirements with professional solvency and the experience of more than 25 years in complex engineering and construction environments for heavy industrial markets of high demand such as mining, gas & oil, or energy, as well as for infrastructure and commerce.

DC&R also offers technical assistance services to businesses that need to interact with engineering and construction companies, from tender and project management to contract administration.

- Details

- Written by: Carlos Delgado

In the world of engineering and construction projects, we often, if not always, meet the natural requirements of effectiveness and efficiency. In fact, a lot of money, time and effort is devoted to ensuring that projects are carried out effectively and efficiently.

Let us begin with the definitions of these terms. Effectiveness is the “Ability to produce the desired effect or to go well for a certain thing", that is the ability to reach the objective, although usually it is not necessarily associated with reaching it in an economic way.

“… the triple constraint: scope, cost and time. If one of these restrictions is compromised, the other two must compensate…”

Efficiency, on the other hand, is the "Ability to perform or fulfill a function properly"1, so here the term "properly" does lead us to the economy of resources with which a goal is reached.

The point is that, while typical market demands seek to obtain both concepts: that the project team achieves effectiveness (the project is completed and begins its operation quickly by overcoming all possible obstacles), and efficiency (within the budget). These two concepts may find themselves opposed very often.

It is thus sought that activities that would normally run in series be executed in parallel, method known as "fast track", or increase resources in order to shorten deadlines, method known as "crashing". It is a known fact within the project execution methodology that "fast track" increases risk, while "crashing" increases cost.

In the Project Management discipline, there is a principle called the triple constraint: scope, cost and time. If one of these restrictions is compromised, the other two must compensate the deviation. Thus, if a project falls behind schedule (delay), it can be realigned with the plan by reducing the scope, increasing the cost or a combination of both actions.

As can be intuitively seen, time impacts often lead to cost increases, even if they do not affect scope. However, changes in scope have both cost and time impacts. Cost impacts may not affect time or scope, but trying to mitigate them usually affects scope, rather than time.

Going back to the concepts of effectiveness and efficiency, it is easy to see that effectiveness is quite related to time, while efficiency is related to cost. Usually what is sought from the beginning in every project is to define the scope ("freeze it") and, on that basis, set the baselines for the cost or "capex" (from "capital expenditure") and the time, reflected in the schedule.

Some common ways to proceed are to start construction work before the engineering is completed (it means "fast track") or speed up the mobilization of the construction team to the construction site to "break the inertia".

I have worked in engineering and construction for more than 25 years and I have heard the phrase "...get in at once to break the inertia" with a really important frequency. The thing is, in construction, the operation is tremendously expensive. If a contractor is to be mobilized to the construction site, it is essential for such mobilized contractor to produce.

Some owners may think that it is the contractor’s responsibility and that they have hired the contractor to solve all the problems. I have news for you: the problems are not the contractor’s, they belong to the project and, when these problems appear, it will be the owner who ends up assuming the costs, in one way or another.

To instruct the mobilization of the contractor without having set the agreed-on conditions as per the contract (i.e. free access to the construction site, areas for temporary facilities, timely supplies when they are the owner’s responsibility, etc.) will certainly lead to problems and claims.

Not only will there be time extensions, whether or not the owner grants them to the contractor, the actual schedule will need to be extended; but the contractor will claim low productivity, stand-by resources and overhead costs for the extension. There will be a conflict with cost overruns and the final date of the project will not be as expected. As a consequence, the philosophy of "get in at once to break inertia" will not improve the final date but, on the contrary, will also cause cost overruns and a controversy.

The reality is that the best, most effective and efficient way to proceed, is to order the mobilization of the contractor when there is reasonable certainty that all the agreed-on conditions are in place, so that the contractor has no argument for subsequent claims.

This may even involve delaying the mobilization order to the construction site, but if that delay ensures that the contractor is mobilized and immediately able to produce, the result will be an optimization of the work schedule and a significant reduction in the risk of cost overruns. Moreover, contractors in the situation of being able to "run" with the execution will be happy to complete the work and get their money as fast as possible.

The fact is that a construction work is like a military operation, success resides in entering and leaving quickly. Delays only mean loss of money for contractors and such contractors will be tempted to try to charge the owner. It is essential for the owner to be able to prove that all the agreed-on conditions were fulfilled, so no claim from a contractor has any base.

In times of change, when agility and economy are needed at all levels, the use of specialized services provides that precise mix of capacity, effectiveness and efficiency that organizations need to succeed.

At DC&R we are able to meet these requirements with professional solvency and the experience of more than 25 years in complex engineering and construction environments for heavy industrial markets of high demand such as mining, gas & oil, or energy, as well as for infrastructure and commerce.

DC&R also offers technical assistance services to businesses that need to interact with engineering and construction companies, from tender and project management to contract administration.