It is hard to overrate the importance of an appropriate and complete design for a project and its execution approach. With no consideration about if we are developing a family house or a big and complex industrial facility, design is fundamental, but the way to carry it out can make all the difference between success and failure.

How can we define a good project? First of all, it must be clear what the desired outcome and the owner's needs are. In small projects, aimed to particular clients, it is likely that the owner knows his/her desires, but it might exist some degree of unknown about his/her needs. The work with an experienced design leader (usually an Architect) must focus primarily on guiding the client along the issues that are not clear, in order to define the final product with the best detail.

When we talk about big complex and highly expensive industrial facilities, it is fundamental to understand that the owner needs to asses the “business case”. Yes, the owner of this type of project carries them out with only one objective: rentability.

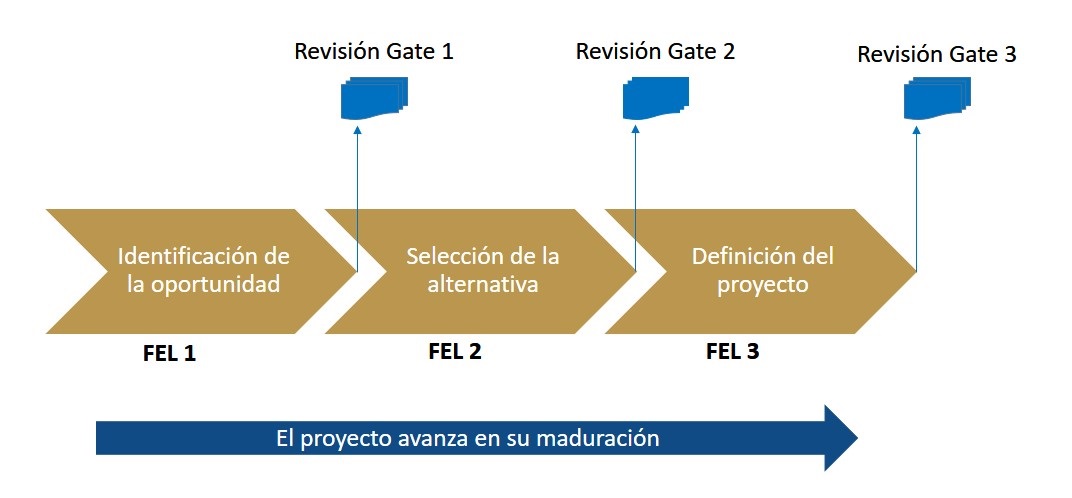

Therefore it is usual to use a “stage gate” approval methodology. The concept is simple, the project is divided into several steps, at the end of each one an assessment is performed and a decision is made about wether continue the project, modify or cancel it.

One of the best known methodologies in the market is the Front-End Loading (FEL). According to the “Construction Industry Institute”, FEL methodology is defined as the process of developing enough strategic information to allow defining the risks of the project and decide how to assign resources to maximise its chances of success.

Typically, a big and complex project goes through three FEL stages:

- FEL-1: It is the opportunity identification or business planning stage, and it is usually called also Preliminary Evaluation. The objective of this phase is to identify and support the opportunity, both technically and economically. This means that it might not exist a design, but only a quite rough economical estimation based on comparisons with similar projects, combined with the specific estimation of some costs. This is the concept studies phase.

- FEL-2: This is the phase of selection and scope development. In this phase possible alternatives are developed by means of trade-off studies, in order to select the more convenient alternative to take advantage of the business opportunity. It is the phase of the Preliminary Feasibility Studies, or “pre- feasibility” studies. Scott and Johnston report that most of the projects will go through two or more preliminary feasibility studies before a final feasibility study is performed

- FEL-3: Phase of project definition and project planning. Basic engineering, execution plan, budget and schedule are developed. This is the time for the Final Feasibility Study. Usually based on the most attractive alternative identified in the previous phase, this study aims to demonstrate conclusively that the project is technically sound and economically viable, produce sufficient support information to make the project bankable for financing institutions and provide a solid base to move to detailed engineering and construction without major changes.

Image: Ingenieros Top

Then the project moves to the execution stage. Consulting firm “Independent Project Analysis” (IPA) names this stage EPCC (Engineering, Procurement, Construction, and Commissioning).

It is in this execution or EPCC stage when the owner shall decide the execution method. The “Project Management Institute” (PMI) mentions in its Construction Extension of the PMBOK Guide as some of the most common methods for projects execution the following:

- Design-bid-build: This is the classic system by means of which the owner engages first the design, then bids the construction based on the engineering documents developed and the awarded bidder simply executes the construction according to the already defined design.

- Design-build: The owner buys the design and the construction to only one contractor based on a concept design and performance specifications developed by the owner.

- EPC (engineering, procurement and construction): Broadly known in the construction industry, the EPC transfers the full responsibility (and risk) for design, procurement and construction to the EPC contractor, who shall develop detailed engineering, buy equipment and supplies, and perform the complete construction to deliver an operative facility to the owner.

- Self-performance: Method used for small projects, usually maintenance. The owner does not engage a company, but performs the work using its own resources.

- IPD (integrated project delivery): This is a collaborative approach focussed on maximising the integration of the project teams, therefore the owner, the designer, the contractor and other stakeholders sign a single contract sharing risks and rewards, based on overall performance.

- Public-Private Partnership (PPP): Generally speaking, these are long term contracts with the State in which the ownership of the investments can be kept by, reverted or transferred to the State, based on the nature and scope of the project and the contractual provisions. These types of contract can be concession, operation and maintenance, management and any other as permitted by law2.

Selection of the project delivery method is of paramount importance. Depending on factors such as schedule, complexity, budget or particular needs of the project, the selection will vary.

When talking about big and expensive projects, it is reasonable that self-performance is usually out of the question. The classic design-bid-build method is the most used, especially in public projects. However, the outcome is not always the best. It is a simple and direct approach, but it requires time to adequately complete each stage and, during construction, a generally antagonistic relationship between the owner and the contractor is observed.

In private projects the arising of extra works and time extension requests lead the relationship between owner and contractor to complex levels of animosity and the results are delays, costs overruns and, sometimes, litigation.

Litigation is much more common in public projects that in the private sector. As an example, the Peruvian General Account Bureau (Contraloría General de la República - CGR) declared in March 2019, one year before the COVID-19 pandemic was declared in Peru, that in the country a total of 867 public construction projects were paralyzed, affecting investments of USD 4,400 million. Those days a local newspaper, Correo, reported that “After a study, the control bureau [CGR] determined that arbitration processes, deficiencies or contract breaches, as well as budgetary limitations of the public institutions are among the main causes that interrupted the execution”.

However, it is interesting to notice that the same year, 2019, Peru achieved a resounding success by delivering on time the construction projects for the Lima 2019 Pan American Games, using the IPD approach thanks to a Government-to-Government (G2G) agreement with the United Kingdom.

In the case of the main venue, La Videna, the project was executed in only 18 months from architectural design to complete construction. A total of 102,000 m2 with a budget over USD 152 million. A true world record.

We can hardly consider that the success of the Pan American Games Lima 2019 project was the product of chance. It is evident that an appropriate approach for project development and project execution allowed that the expertise, methodology and hard work of thousands of professionals get the maximum positive outcome.

In contrast, not long ago, in July 2021, the International Center for Settlement of Investment Disputes (CIADI) established after 4 years of an arbitral process that the Peruvian State failed to the existing concession contract with the Consortium Metro de Lima Line 2. The Consortium, formed by Cosapi, Impregilo, Iridium Concesiones de Infraestructura -subsidiary of ACS-, Vialia Sociedad Gestora de Concesiones de Infraestructura -subsidiary of FCC-, Ansaldo Breda and Ansaldo STS, filed the lawsuit in February 2017 with CIADI claiming compensation of more than USD 700 million and, following the July ruling in favour of the Consortium, in August 2021 the Spanish construction companies ACS and FCC, together with the Italian Impregilo and Ansaldo have filed a second arbitration claim against the Peruvian State.

Perhaps because of that, Peru has launched more projects using G2G agreements which allow approaches such as IPD, among them the new Central Highway and the Reconstruction With Changes.

In times of change, when agility and economy are needed at all levels, the use of specialized services provides that precise mix of capacity, effectiveness and efficiency that organizations need to succeed.

At DC&R we are able to meet these requirements with professional solvency and the experience of more than 25 years in complex engineering and construction environments for heavy industrial markets of high demand such as mining, gas & oil, or energy, as well as for infrastructure and commerce.

DC&R also offers technical assistance services to businesses that need to interact with engineering and construction companies, from tender and project management to contract administration.